structure of concrete can be defined as the shape, size, amount and distributions of different components or phases of concrete.

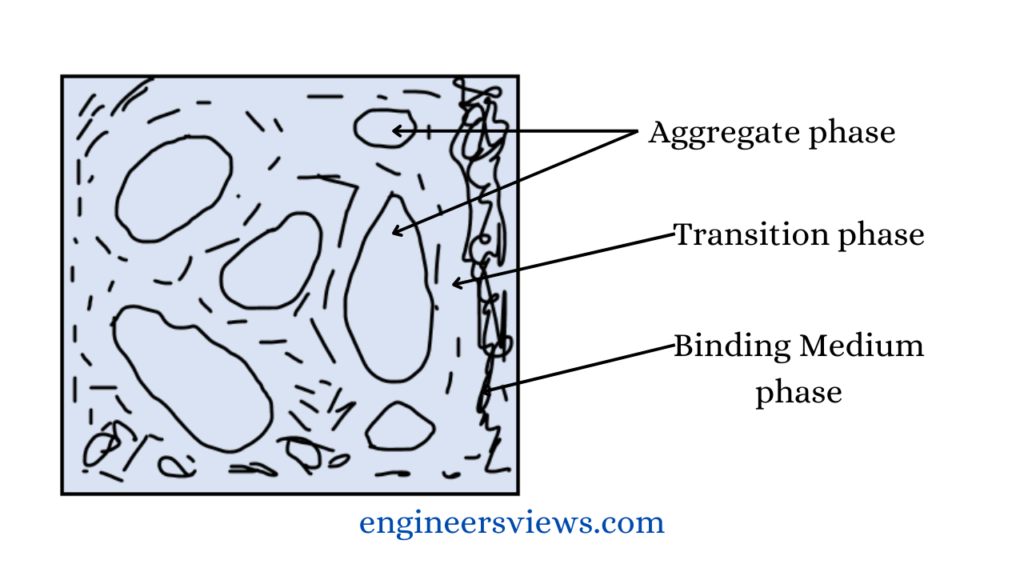

Concrete as a three phase system

concrete is mainly composed of following three phases

- Aggregate phase ( Aggregate of varying size )

- Binding Medium phase ( cement paste / Mortar phase )

- Transition zone phase ( exists between aggregate and binding medium phase )

Structure of the Aggregate phase

- Aggregate phase is responsible for unit weight of the concrete , elastic modulus and dimensional stability of the concrete because these properties are based on physical characteristics.

- Aggregate phase occupies about (60-70)% of the total volume of concrete mix in most of the concrete.

- The chemical composition of aggregate is of less importance than the physical properties of the mineral that formed the aggregate.

- Aggregate is the strongest phase of concrete.

- The strength of concrete is greatly affected by the shape and size of aggregate.

- When there is larger size of aggregate in concrete, there will be higher tendency for water films to accumulate very next to the aggregate surface and this results in weakening the cement paste aggregate transition zone. This phenomena is also known as internal bleeding.

Some terms :

Bleeding : Bleeding is a phenomena in freshly placed concrete where free water in the concrete mix rises upward to the surface due to settlement of heavier solid particles by gravity action.

Internal Bleeding :In certain circumstances though bleeding water does not come up to the surface of concrete but bleeding does take place. The bleeding water gets trapped on the underside of coarse aggregate or of reinforcements. This is known as internal bleeding.

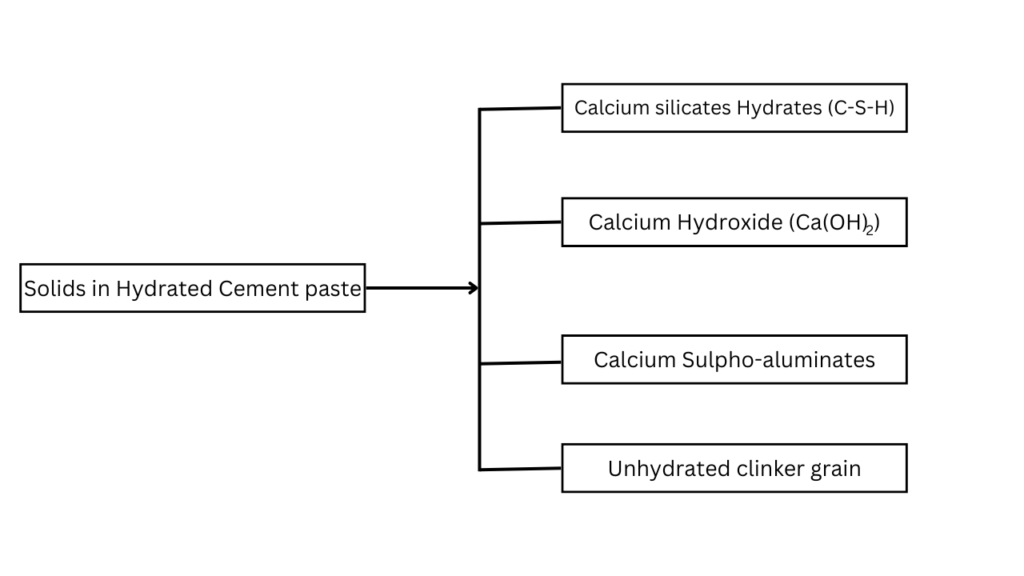

Structure of Hydrated cement paste phase (HCP)

Binding medium phase is the most significant phase of cement concrete because it influence the overall behavior of hardened concrete. Hydrated cement phase (hcp) affects many characteristics and strength governing properties of concrete like strength , durability , creep, shrinkage and elastic properties of the hardened concrete

Calcium Silicate Hydrates (C-S-H)

- it is generally known as C-S-H gel or tobermorite gel.

- It is very much responsible in generation of cementitious property in cement .

- It occupies the major volume of solid. ( i.e. about (50-60)% of the volume of solid .

- Its strength is due to Vender wall force.

- Exact structure of C-S-H is not known .

Calcium Hydroxide (Ca(OH)2)

- It has minor contribution in structural property .

- also known as portlandite.

- Calcium Hydroxide (Ca(OH)2) crystal constitute (20-25)% of total volume of hydrated cement paste.

- It has lower strength contribution as compared to C-S-H.

- It has tendency to form large crystal with distinctive hexagonal prism morphology.

Calcium Sulpho-aluminates

- It also has very less contribution in structural property of hcp or concrete.

- It constitutes about (15-20)% of total solid volume of hcp.

- Ettringites and monosulphate

- Presence of Monosulphate hydrates in concrete is susceptible to Sulphur attack.

Unhydrated clinker grain

- The amount of unhydrated clinker grain in cement concrete depends on the size of cement particles and degree of hydration of cement.

- The size of clinker particles varies from 1μm to 50μm.

- The hydration of smaller particles takes place at first and the size of larger particles goes on decreasing with time during hydration.

- Some unhydrated clinker grains may be found in the micro structure of hydrated cement paste , even after long duration of hydration.

Voids in Hydrated Cement paste

The hydrated cement paste consists certain degree of porosity . Various types of void in hcp are responsible for this porosity of hcp . Significant types of voids are explained below.

Inter layer space in C-S-H

- It occupies about 28% porosity in solid C-S-H.

- Roughly the space vary from 5Å to 25Å.

- This types of voids are too small to have a significant impact on the strength and durability of concrete.

Capillary Voids

- These type of voids are the space which are not filled by the solid component of hcp.

- They are irregular in shape.

- Size of capillary voids may vary from 10μm to 50μm , even it can go outside this range.

- Mainly , the dimensions and quantity of capillary voids depends on w/c ratio and degree of hydration of cement.

- Voids which are greater than 50μm are referred as macropore and they are supposed to be detrimental to strength and permeability.

- And the voids which are smaller than 50μm are called as micropore and they are supposed to be more responsible to shrinkage and creep.

Air voids

- Air voids are spherical in shape.

- Entrained air voids are generally 50μm to 200μm in size.

- But entrapped air voids are relatively larger in size . They might be as large as 3mm.

- Air voids are capable of adversely affecting the strength and impermeability of concrete.

Strength of Hydrated Cement Paste (HCP)

- Strength in solid product of hcp is due to vendarwalls force of attraction.

- Small crystals of C-S-H possess enormous surface area and adhesive capability which tends to adhere strongly not only to each other but also to low surface solid like calcium hydroxide, unhydrated cement clinker grains and Fine and Coarse aggregate particles.

- Strength of hcp is inversely proportional to porosity.

- Voids in hcp depend on the extent of mixing and degree of hydration.

Dimensional Stability of HCP ( Effects of relative humidity , stress and degree of saturation on HCP)

- With increase in degree of saturation , hcp becomes less stable.

- When hydrated cement paste is directly exposed to environmental humidity , it starts to loose water and shrinks.

- As soon as Relative humidity (RH) drops below 100% , free water held in large cavity ( cavity with larger dimension >50nm) began to escape to the environment . At this point little shrinkage occurs.

- Factors or mechanisms which are responsible for drying shrinkage are also responsible for creep of hcp.

- Creep strain can occur even at 100% relative humidity.

Durability of Hydrated Cement Paste (HCP)

- HCP is alkaline in nature so its exposure to acids or acidic water is detrimental.

- permeability is prime factor for durability.

- Strength and permeability both are closely related to the capillary porosity or solid/space ratio.

Transition Zone phase

Transition zone is the space between aggregate particles and hydrated cement paste (hcp). It exists as thin cell ( in range (10-50)μm). Formation of transition can result to poor bonding between hcp and aggregate particles and formation of thin film of water layer around the aggregate particles during mixing of concrete.

owing to higher water cement ratio (w/c) , the transition zone is more porous than the mortar mixture. Due to low strength , micro cracking often forms within the transition zone even before applying the load. Generally the transition zone is the weakest zone in concrete although it occupy less volume.

Cement paste or mortar will always be stronger than the concrete provided that they have the same w/c ratio and are tested in same condition and same age.Permeability of concrete is more higher than the cement paste.Under the same loading Constituents of concrete ( Aggregate and hcp ) can show the linear behavior while concrete itself shows non-linear behavior.