In steel structures, web buckling and web crippling are two types of failures that can occur in the webs of steel beams, especially in those subjected to significant loads. Understanding these failure modes is crucial for ensuring the safety and integrity of steel structures.

Web Buckling

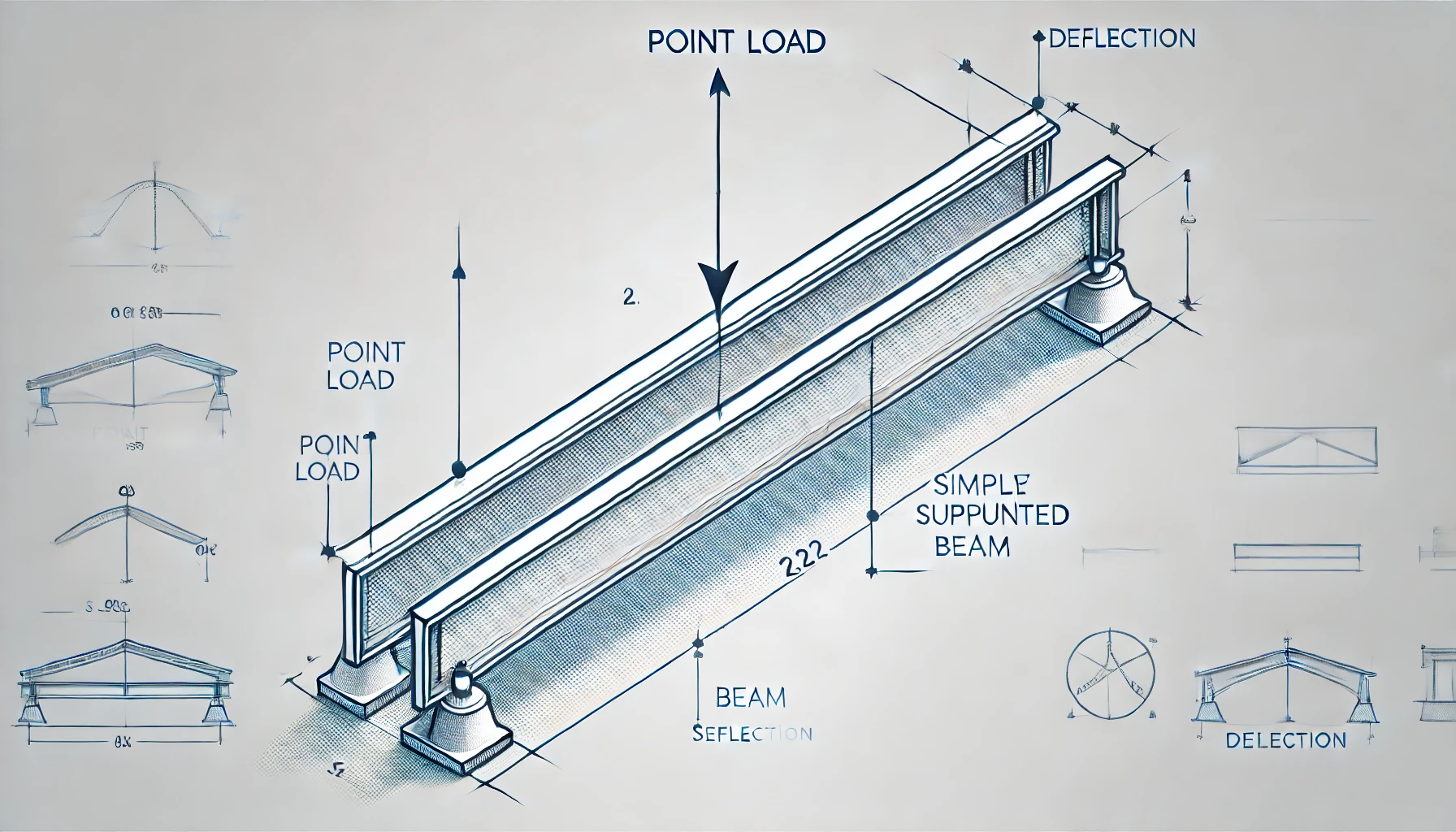

Web buckling occurs when the web of a steel beam, which is the vertical section connecting the top and bottom flanges, fails due to instability under compressive stress. This type of failure is similar to column buckling but occurs in the web of the beam.

Mechanism:

- When a beam is subjected to a high load, especially near the supports or points of concentrated loads, the compressive force on the web increases.

- If the web is too slender (i.e., has a high height-to-thickness ratio), it may not have sufficient stiffness to resist this compressive force, leading to lateral-torsional instability.

- The web buckles out of its plane, leading to a significant reduction in load-carrying capacity.

Factors Influencing Web Buckling:

- Height-to-Thickness Ratio: A higher ratio increases the likelihood of buckling.

- Web Stiffeners: Adding stiffeners can help prevent buckling by increasing the rigidity of the web.

- Loading Conditions: Concentrated loads and high shear forces near supports increase the risk of web buckling.

Web Crippling

Web crippling is a localized failure that occurs at the points where concentrated loads or reactions are applied to the flange of a steel beam. This failure is due to the high compressive stresses that develop in the web directly under or adjacent to the load application points.

Mechanism:

- When a concentrated load is applied near the edge of a beam’s flange (e.g., at a support or where another structural element bears onto the beam), the web experiences a high localized compressive stress.

- If the web is too thin or lacks adequate support, it can crush or crumple under this load, leading to a failure known as crippling.

- Web crippling is a plastic deformation failure, where the material yields under compressive stress.

Factors Influencing Web Crippling:

- Web Thickness: Thicker webs are more resistant to crippling.

- Flange Width: Wider flanges distribute the load more effectively, reducing stress concentrations.

- Load Location: Loads applied closer to the edge of the flange are more likely to cause crippling.

- Presence of Stiffeners: Stiffeners can reinforce the web and help distribute the load more evenly, preventing crippling.

Prevention and Design Considerations

To prevent both web buckling and web crippling, engineers must carefully consider the design of the beam, including the dimensions of the web, the use of stiffeners, and the distribution of loads. Design codes provide guidelines and formulas for calculating the critical loads for both web buckling and web crippling, ensuring that beams are designed with sufficient safety margins.

Real World Failure Examples of Web Buckling and Web Crippling

Web buckling and web crippling are failure modes that, while often identified and mitigated in the design phase, have occurred in real structures. However, documented cases of large-scale structural failures specifically attributed to these phenomena can be somewhat difficult to find because they often occur in conjunction with other factors. That said, there are notable examples where web instability played a role:

1. The Collapse of the I-35W Mississippi River Bridge (2007)

- Location: Minneapolis, Minnesota, USA

- Event: The I-35W bridge collapse was a tragic event where the bridge suddenly collapsed during rush hour, resulting in the deaths of 13 people and injuring 145 others.

- Web Buckling Role: The National Transportation Safety Board (NTSB) investigation found that the primary cause of the collapse was the failure of a gusset plate due to inadequate thickness. However, contributing factors included the buckling of web elements and inadequate load distribution that put additional stress on these critical connections. This failure highlighted the importance of considering web buckling in the design and assessment of similar structures.

2. The Collapse of the Point Pleasant Bridge (Silver Bridge) (1967)

- Location: Point Pleasant, West Virginia, USA

- Event: The collapse of the Silver Bridge resulted in 46 fatalities. The bridge, built in 1928, suddenly failed under the load of rush-hour traffic.

- Web Crippling Role: While the primary cause was the failure of an eyebar, web crippling and local buckling of the steel beams were secondary failure modes that contributed to the collapse. The inability of the web to sustain localized stresses led to a rapid propagation of failure across the bridge structure.

3. The Collapse of the Hyatt Regency Walkway (1981)

- Location: Kansas City, Missouri, USA

- Event: This disaster involved the collapse of a suspended walkway, killing 114 people and injuring over 200. It remains one of the deadliest structural failures in U.S. history.

- Web Crippling Role: While the immediate cause of the collapse was a connection failure, detailed investigations revealed that the web of the steel beams supporting the walkways experienced crippling due to poor load transfer and inadequate design, leading to the connection failure and subsequent collapse.

Lessons and Modern Implications:

These events underscore the critical importance of thoroughly understanding and designing for web crippling and web buckling in structural elements, especially under high-stress or load-bearing conditions. Modern design codes and standards now include more stringent requirements to address these failure modes, incorporating lessons learned from such tragic incidents.